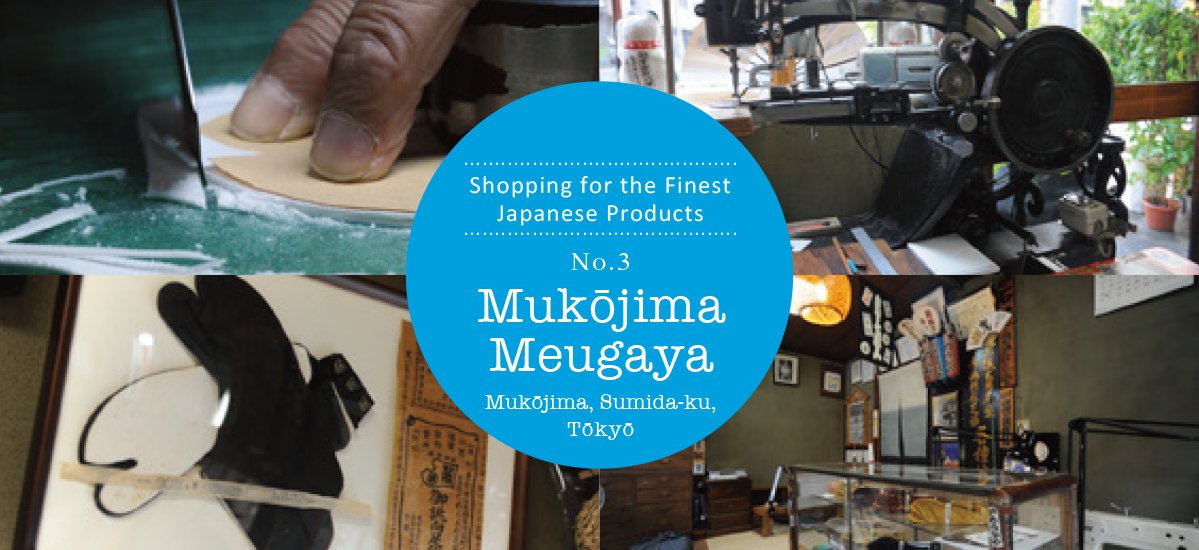

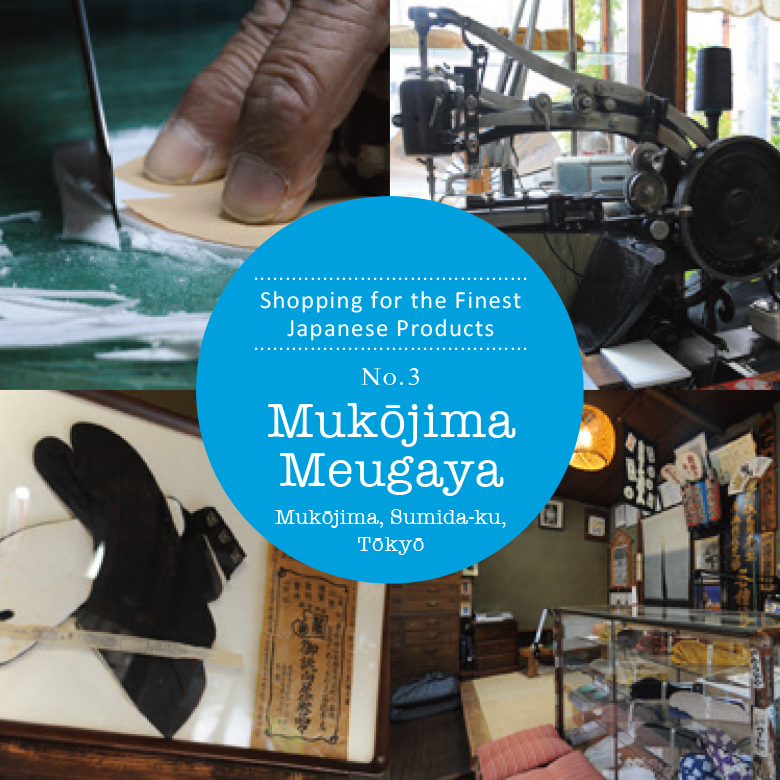

A bespoke tabi store in Tokyo has been behind geisha chic for over 150 years. What’s their secret? And why do kimono wearers from Tokyo’s geisha districts still insist on bespoke tabi from Mukōjima Meugaya?

Text : 水口まり Mari Minakuchi / Photos : 菅原孝司 Koji Sugawara / English Version : Judy Evans

Keyword : Shopping for the Finest Japanese Products Series / Kimono / Tabi / Sumida Ku / Famous Shops / Edo Period / Tokyo / Artisans / Traditional Skills / Shopping

When it comes to looking smart in kimono, stylish, wrinkle-free tabi are a must. In days gone by, fashionable “Edokko” (those born and raised in Tokyo or old Edo) were fastidious about footwear, lavishing much attention on their feet.

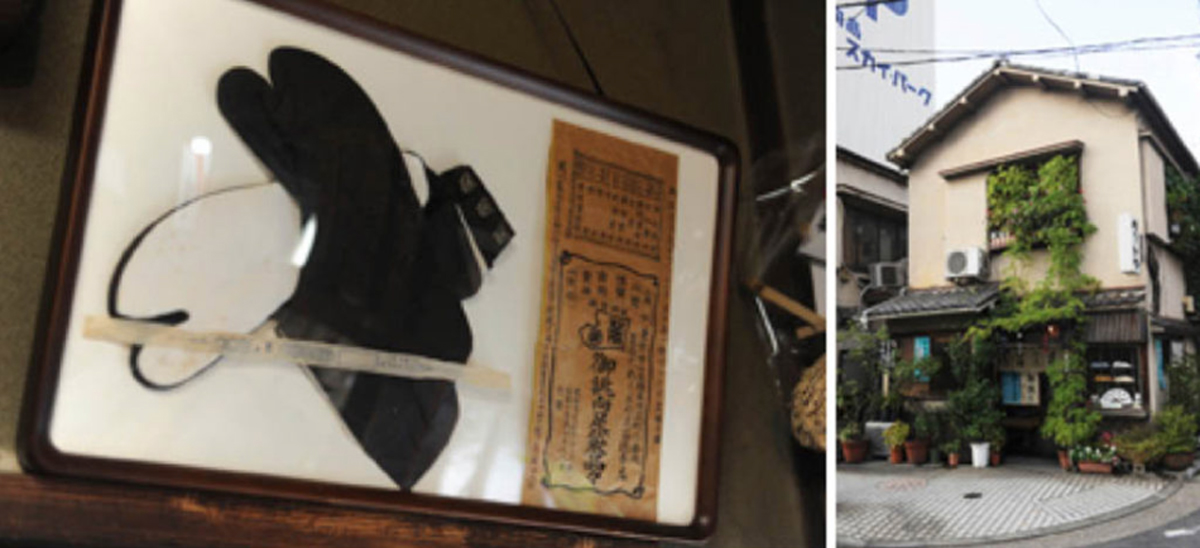

Mukōjima Meugaya (pronounced “Myōgaya”) is a long-established bespoke tabi maker that has provided made-to-measure tabi, those quintessentially Japanese divided socks worn with kimono, for Tokyo’s geisha and other discerning wearers of kimono for over 150 years.

Mukōjima, where the shop is located, still retains the air of Tokyo’s traditional shitamachi districts. It is here that Mukōjima Meugaya continue to make the Edo-style tabi preferred by the women of Tokyo’s geisha quarter, who want their feet to look slender and elegant.

To achieve the slender Edo-style look, the ladies of Edo traditionally liked to wear their tabi a little on the tight side. Compared to the rounded silhouette of traditional Kyōto-style tabi, Edo-style tabi are narrower, giving the foot a more slender line.

The business was established in 1867 as an off-shoot of a much older tabi maker. They originally operated in Asakusa, but moved to Mukōjima in around 1923. The current head of the business, fifth generation Yoshikazu Ishii, continues to maintain the techniques and traditions that have been handed down for generations. Over 70 percent of the tabi sold here are made-to-measure, based on individual patterns cut for each customer.

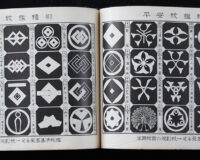

There are around twenty separate steps involved in the making of a pair of bespoke tabi, which makes them a cut above the mass-produced tabi on offer in many places, both in terms of fit and of durability. For instance, while the fabric for mass-produced tabi is generally cut using a die-cutting press, at Meugaya, the fabric for each pair is cut by hand.

All the work is done in-house by Ishii san, assisted by his wife, and son. Having a pair of bespoke tabi made for the very first time is a comparatively long process. Once the pattern has been taken, a trial pair is made for the customer to wear for three months. This allows for adjustments to be made to the pattern to ensure comfort and a perfect fit.

For customers who don’t have that long to wait, or who have never worn genuine hand-made tabi before and are not sure they want to commit to having them made to order, Meugaya have a line of ready-made tabi. As you would expect, even these ready-made tabi are exceptionally well made and feel extraordinarily comfortable. The white calico ready-made tabi come in up to four different widths, depending on the size. While there is a minimum first order of six pairs for made-to-order tabi, there is no minimum purchase when buying them off the shelf. It’s even possible, for an additional charge, to buy different sizes for left and right feet.

In finishing the tabi to the highest standard and ensuring suitability for their end use, several factors are taken into account, both when taking measurements and in making the final product. The age of the customer is considered, as well as the time of day that the measurements are being taken. The purpose of the tabi also needs to be considered, such as whether they are to be worn on stage or for everyday use, and whether the wearer will be spending long periods sitting on tatami in the traditional style. Depending on individual wear patterns, extra stitching or cushioning can be added to ensure comfort and durability.

A great deal of care is put into taking the measurements for customers. The Ishii family still use the same type of tape measure and special ruler known as a “mongi”, that they have used for generations, carefully measuring both right and left feet.

Ishii-san says that people’s feet change shape after ten years or so. He keeps his customers’ patterns for as long as they want him to, but sometimes measurements do have to be retaken.

With such care and attention to detail, it’s easy to see why Mukōjima Meugaya’s loyal customers keep coming back, generation after generation.

Note:

No appointment is needed to visit Mukōjima Meugaya, but the store would appreciate a call in advance (03-3626-1413, in Japanese) if you intend to have measurements taken for bespoke (atsurae) tabi. Current prices can be checked on Mukōjima Meugaya’s website (in Japanese). http://www.mukoujima-meugaya.com/index.html