Although we live in an era where most commodities are mass-produced, there is still a fascination with traditional hand-crafted goods. A household item found in any Japanese home in the past was the wooden oke (pail or bucket). These humble wooden pails, with their lovely warm texture, are the product of skills and techniques honed over the years by the artisans who make them.

Text : Sasaki Takashi / Photos : 平島 格 Kaku Hirashima / English Version : Judy Evans

Keyword : Wakayama Prefecture / Traditional Skills / Wooden buckets

The secret behind great-tasting rice and miso

Wooden pails and barrels – essential items of the past

Okehama is an old-fashioned oke shop at the side of Route 311 (formerly the Nakahechi route of the Kumano Kodō pilgrimage), just outside Nakahechicho Nonaka village in Wakayama Prefecture. Calling it a shop might be overstating things somewhat – this is actually an ordinary house with wooden oke (pails) and taru (barrels) for sale in a parlour just inside the front door. At the side of the house is a workshop filled with oke and taru in various stages of completion and on the other side the road, beneath a large miso barrel that serves as a sign, is the simple word, ‘Okeya’ (おけ屋).

So simple in fact, it would be easy to drive right past it.

Hamaji Matsumoto, the ever-smiling owner of Okehama, explains why miso and tsukemono (pickled vegetables) made in wooden oke taste so much better than the same products made in plastic or ceramic containers. Apparently, a fair bit of moisture seeps out during the pickling process. In plastic or ceramic containers this moisture has nowhere to go, resulting in somewhat mushy pickles. However, wood, according to Matsumoto san, ‘breathes’, allowing the moisture to wick away from the contents, yielding a superior result.

Born in 1934, Matsumoto san became apprenticed to an oke craftsman just a few years after the end of the war. There being no plastic back then, wooden pails and barrels were an essential part of daily life. After completing his apprenticeship and setting up his own business, Matsumoto san’s biggest client was a large miso manufacturer in Osaka. In those days he used to make countless tiny barrels, just big enough to hold one kilogram of miso, every day.

Orders for wooden pails and barrels decreased dramatically when the use of cheap plastic goods became widespread and Matsumoto san was forced to find employment elsewhere. However, years later when he returned to his family home to care for his elderly mother, he picked up his tools once again and has been making pails and barrels for domestic use ever since.

Different materials for different purposes.

So, what is the difference between an oke and a taru? Generally speaking, wooden pails without lids are classed as oke, while those with lids are called taru. However, Matsumoto san begs to differ. He classifies his products as either oke or taru according to their intended purpose, regardless of whether they have lids or not. He says that a vessel which is frequently filled and emptied is a bucket (oke), whereas one used to store liquids and other materials for long periods of time is a barrel (taru). Different types of planks are used for the sides of each type of vessel.

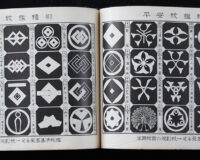

As the photo above shows, the wood grain of the plank depends on the angle at which the plank was cut from the log. A straight grain (柾目 masame) on the broad face of the plank is obtained by sawing directly towards the centre of the log across the annular growth rings (as with quarter-sawn or rift-sawn planks). In contrast, a wavy ‘cathedral’ grain pattern (板目 itame) on the broad face results when planks are ‘flat-sawn’, or cut more or less along the growth rings. The two different grain patterns are also clearly visible in the photo of the wooden lids further down this page.

While the layperson is content just to admire the beauty of the wood grain, the craftsman knows exactly how to use the inherent properties of the material to its best advantage.

Straight grain planks absorb and release moisture more readily, so pails made from this type of timber are perfect for holding cooked rice. Another advantage is that they dry very quickly in the shade after washing. In contrast, moisture passes through the wavy grained flat-sawn planks less easily, so this type of timber is suitable for making sake and miso barrels. And, as the timber of the barrels absorbs moisture, the planks expand against each other, becoming even more water-tight.

Everyday objects made to last a lifetime

Rice paste adhesive is used to temporarily hold the planks together while Matsumoto san completes the oke, but this paste is not intended as a permanent adhesive. Providing that the edges of the planks have been cut to the precise angle and the sides of the oke describe a perfect circle, all it takes to make the oke water-tight is to insert the base of the pail and push it into place.

Matsumoto san says with pride that, used correctly, an oke will last a lifetime. People sometimes bring old, broken oke to him for repairs. He finds that the sides and base of the oke are usually in good condition, so once the outer hoop bindings are replaced, these old oke are as good as new.

Although Matsumoto san makes whatever his customers order (from small sake cups to big bathtubs), his most popular product at the moment is ohitsu containers used to hold cooked rice.

Fans of Okehama’s wooden ohitsu claim that not only does the Kumano cedar they are made from have a lovely fragrance, but also, because the wood absorbs excess steam and moisture from the just-cooked rice, these ohitsu make the rice taste even better. And not only that, but as the rice dries out, it re-absorbs the moisture held in the wood, keeping each grain of rice plump and moist even if it sits in the wooden container for hours.

It seems that Matsumoto san’s wooden oke and taru live on as trees, absorbing and releasing moisture, even after being made into household goods.

Okehama

Address:

1253 Nakahechichō Nonaka, Tanabe City, Wakayama Prefecture

Tel: 0739-65-0561 (in Japanese only)

Hours: 08:00 – 18:00

Days: Closed irregularly

Access

By car: About 30 km/ 45 minutes via Route 311 from the Kamitomida Interchange on the Kisei Expressway.

By train and bus: About 1 hour 30 minutes on the Ryūjin Bus (Kumano Hongu Line) from Kii-Tanabe Station on the JR Kisei Line. Get off the bus at ‘Kokudō Kasamatsu’ bus stop and walk about 5 minutes.